- Design the most durable welds;

- Coordinate your welders and monitor your production using dashboards;

- Automatically identify and trace NDT;

- Create your regulatory documentation (welding data book, end of fabrication report – RFF).

- Avoid non-compliances and build customer confidence

- Reduce the time spent on technical documentation management by 50%.

- Optimize your production processes

- Ensure the quality and documentary conformity of your welding projects (WPS/PQR/WPQR, plans, report)

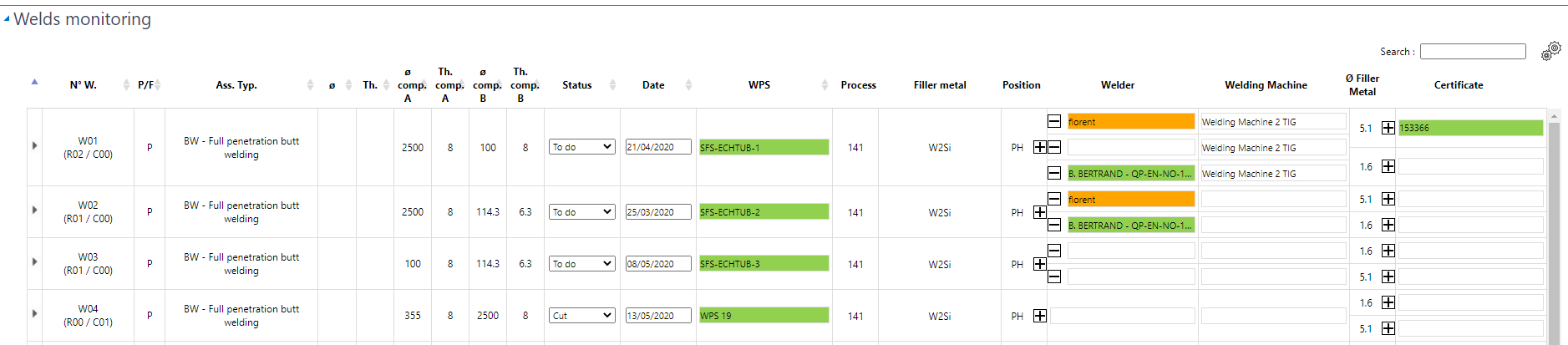

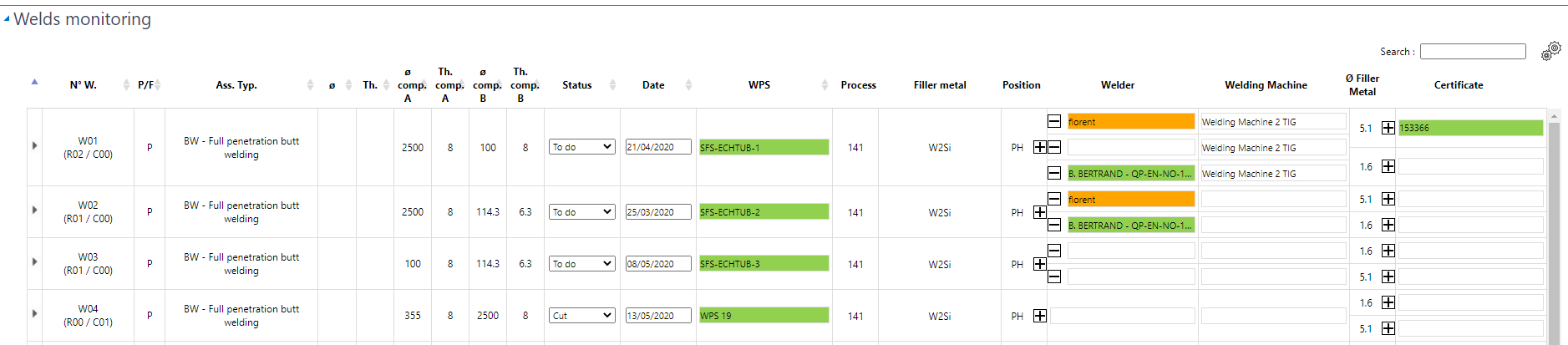

- Monitor the fabrication of your welds on a daily basis.

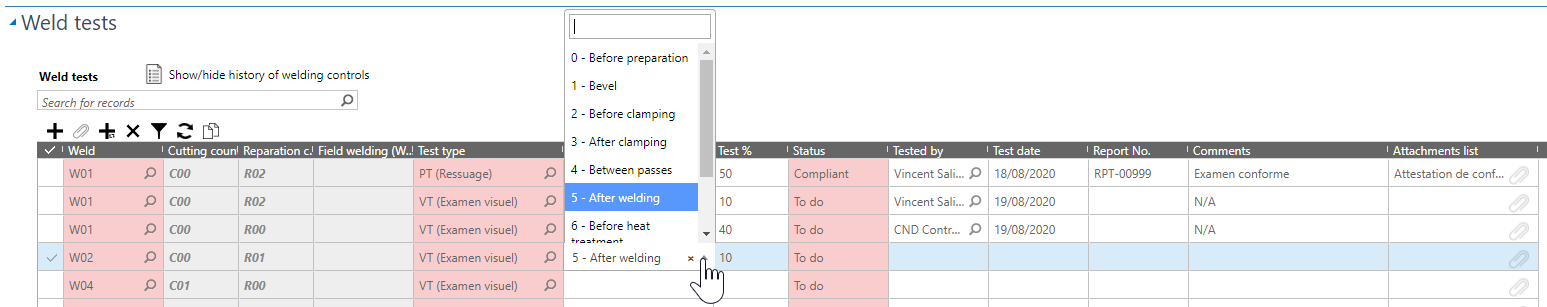

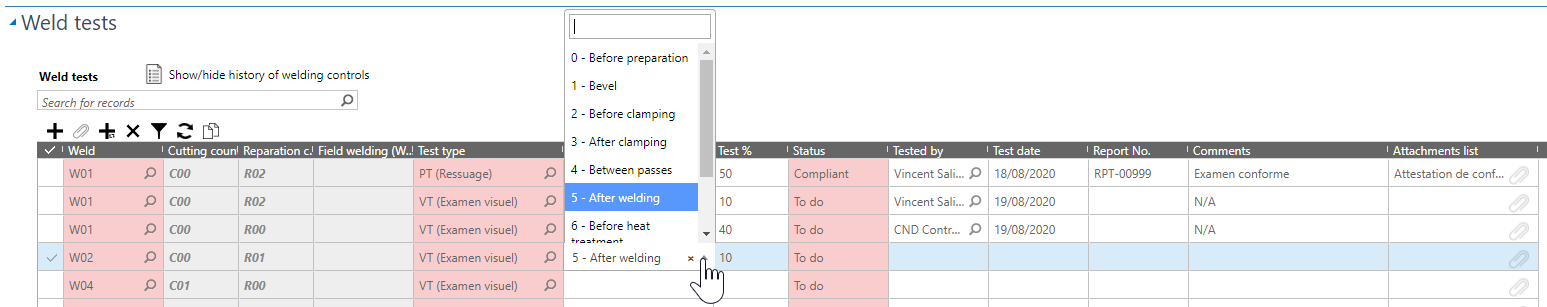

- Keep an eye on the overall NDT list of your production.

- Build your own customizable welding databook/manufacturer’s files in PDFs and in several languages (German, English, Italian and French)

- ASME IX, AWS D1.1, AWS B2.1, ISO 15614-1, ISO 9606-1 fully supported

- Integrated welding quality assurance (ISO 3834, EN 15085, EN 1090) and integration of your specifications (RCC-M, CODETI, CODAP, etc.) for each of your business activities.

- Personalizable WPS form

- Complete and editable integrated databases of materials, consumables, standards, preparation, and pass diagrams

- Fully customizable performance monitoring dashboards

- Download the brochure and sign up for a demonstration to learn more.

- Launch Sirfull Welding easily with the additional “Swiftdata” module for importing historical data.

SIRFULL™ Welding is used by companies subject to strong regulatory requirements; such as Emerson Process Management (nuclear) and GRTgaz (natural gas), but also subcontractors and boilermakers in the oil & gas, pharmaceutical, chemical, food processing, transport, shipbuilding, handling, metal construction sectors.

Need more information? Go to the SIRFULL Welding FAQ.

Welding project management

Find in one place all the information related to your welding projects and follow their progress.

WPS automatic drafting

Sirfull finds the optimal PQR covering the parameters of the weld to be performed in your case and writes a compliant WPS based on this PQR.

Weld mapping

Locate the welds and components of your equipment to be assembled on its plan and export it.

Welders and WPQR always qualified

Don’t miss any validation end date. Requalify every 6 months the WPQR, attach the supporting document and find in one click the requalification weld in the welder’s assembly history.

- Know how the welding was carried out, by whom, with which qualifications, material certificates, welding machines, …

- Easily assign the most qualified welder(s) to execute the job.

- Find the material and consumable certificates available for each weld.

- Keep an eye on the overall NDT list of your production;

- Trace the reports of each NDC;

- Assign an internal or external controller for each NDT to be carried out.