Who is NEU-JKF FEVI?

- History: Designer since 1956 of industrial fans (centrifugal, axial, radial) standard / specific.

- Site of La Vespière, Normandy, France

- 85 employees

- Markets: Agriculture, food industry, cement, metallurgy, glass industry

- NEU-JKF Group: NEU-JKF Fevi belongs to the NEU-JKF group, specialized in air technology11 sites, €150M/CA

NEU-JKF FEVI has a large base of qualifications and welding procedures (hundreds of Certifications/PQR/WPS). Having such a database allows the company to be flexible in the design and manufacture of high-quality, high-performance fans for various markets.

Indeed, this welding database allows NEU-JKF FEVI to produce equipment of different sizes and arrangements using a wide range of materials:

- Carbon, medium, and high yield strength steels Stainless steels

- AISI 304 L, 316 L, 316Ti, 904 L, 2205, …

- Aluminum, Titanium Special alloys : Hastelloy, Incolloy, Inconel, …

- CASTOLIN CDP type hardened steel plates

On the other hand, such a welding database can become heavy to maintain, i.e.:

- Renewal of Welders Qualifications

- Updating of Welding Procedure Qualifications

At the same time, NEU-JKF FEVI is bound by obligations of quality and traceability of welding; generating even more “administrative” tasks:

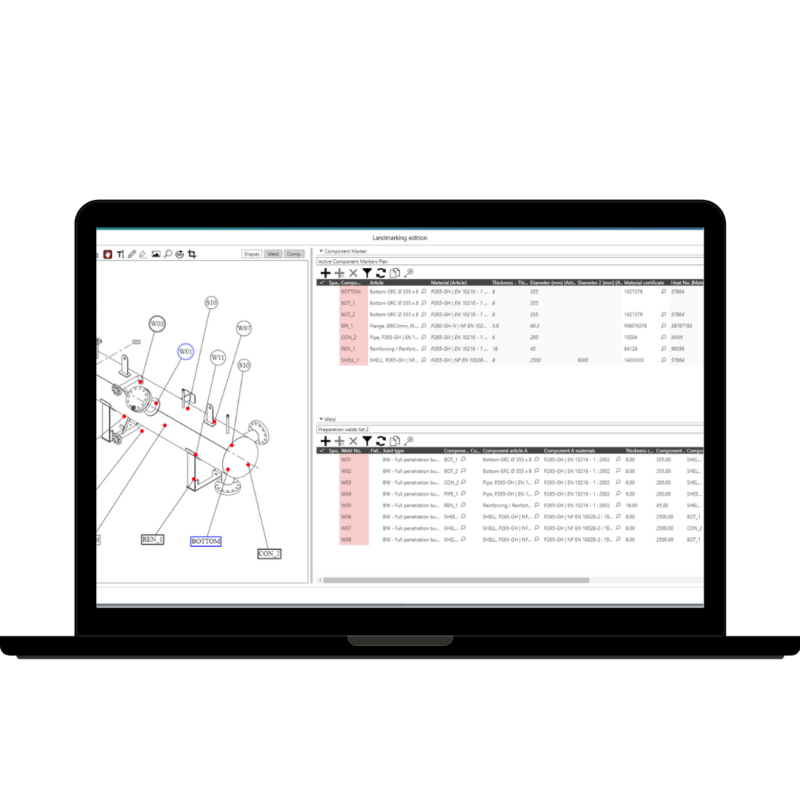

- Drafting of Welding Procedure Descriptions

- Editing of traceability documents: welding logbook / manufacturer documentation

However, these obligations can become problematic when they are processed on Excel tables as was the case for Neu-JKF FEVI and many other manufacturers.

“We had a multitude of unrelated tables,” comments Benoit Dumont, IWE and lead user of Sirfull Welding at Neu JKF FEVI.

“It’s not easy to keep track of all the end of validity dates, the Domains of Validity of our qualifications”.

Here is a non-exhaustive list of the disadvantages of managing welding traceability on office tools:

- Decentralization of information,

- Difficulty to synchronize tables with several users,

- Multiplicity of tools to compile a manufacturer file in PDF

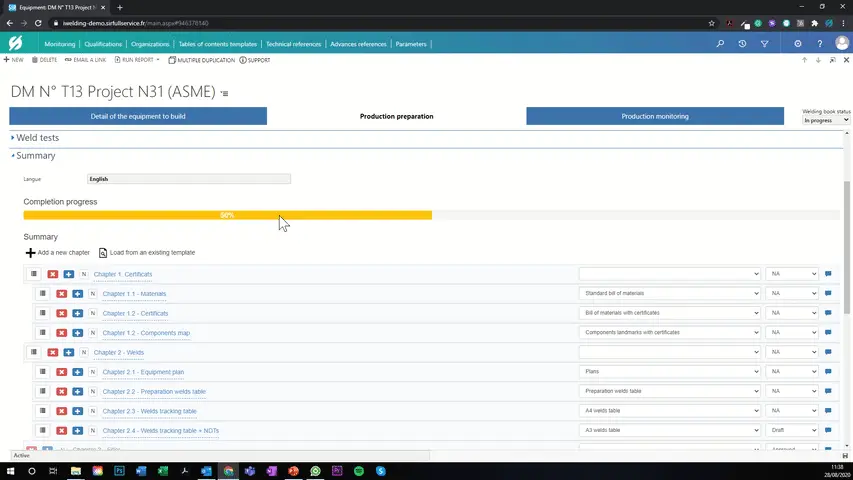

- To simplify the management of all the welding documentation of the La Vespière site

- Centralize the welding documentation in a single work environment

Sirfull Welding PREMIUM version

“We identified Sirfull Welding as the right solution to centralize our operations related to the welding part of our production site” adds Mr. Dumont.

Sirfull Welding benefits:

- Fast deployment thanks to the Sirfull Cloud.

- No installation, no adaptation.

- Training done remotely.

RESULTS

- Simplified management of the company’s qualifications database,

- Save time in the operations related to the update of the database,

- High potential for time savings in the editing of welding books.

According to Mr. Dumont, “Sirfull Welding meets our expectations because it allows us to search our database more quickly. For example, all of our welding know how it can be read right from the software’s home page. “Sirfull makes it easier to renew and track our qualifications”.

“The navigation is pleasant and greatly simplifies our management” adds Damien Le Nouaille, Coordinator and Welding Referent.

“After one year of use, it is satisfactory, but also promising in terms of time saving for the edition of our welding books to come.”