What is weld traceability? The Welding Manufacturer Data Report Checklist.

Weld Traceability provides information on the:

□ weld procedure used,

□ the identification of the welder,

□ date when welded,

□ unique identification number of the weld,

□ drawing number,

□ weld consumable batch number,

□ materials welded,

□ NDE / NDT report numbers,

□ inspector identification,

□ and inspection results.

MDR table of content

Manufacturer Data Report (MDR) is the main record where to track this information.

The MDR is a report produced by the Manufacturer and submitted to the company Welding Coordinator for review and approval, certifying that all items have been constructed, inspected, and tested in compliance with the requirements of the applicable standard(s), design drawings, and specifications.

This report shall include and is not limited to (where applicable):

□ material test certificates,

□ welder qualifications,

□ qualified weld procedures and supporting Weld Procedure Qualification Record (WPQR),

□ inspection records,

□ Non Destructive Examination (or Testing) reports,

□ heat treatment records,

□ pressure test certificates,

□ Inspection and Test Plan,

□ weld maps and weld traceability records,

□ weld consumable certificates,

□ dimensional records,

□ coating records calibration certificates,

□ statutory approvals,

□ concessions/deviations,

□ certificates of any other tests or inspections as required by applicable standards or specifications.

Download our MDR sample for free.

General requirements for Welding traceability

It exists Minimum Quality Criteria for Equipment Classes depending on your applicable standards which are:

□ Structural (ex.AWS D1.1 – US);

□ Cranes and lifting devices ex. ASME B30);

□ Pressure Piping (ex. AS4041 -Australia/NZ);

□ Boilers and Pressure Vessels (ex. Pressurized Equipment Directive -EU);

□ Storage Tanks (ex. API 620).

But this article doesn’t cover these levels of detail. Please, refer to your applicable standards.

What norms to adopt when it comes to Welding traceability?

However, there are general requirements for all Welding. They can be found in the ISO 3834 for specifying quality requirements for fusion welding provides assurance.

Welding Manufacturer Data Samples

□ Plans, Specifications & Weld Traceability

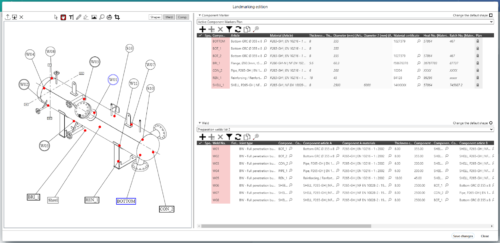

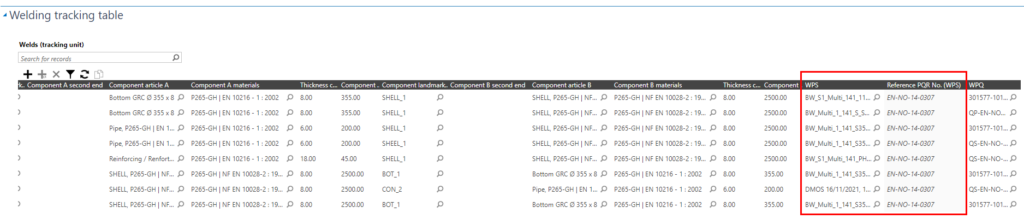

All work must be carried out in strict accordance with any drawings or specifications issued by the company. Marked-up drawings (eg. weld maps) detailing all welded joint locations and weld identification numbers shall be provided by the contractor with corresponding weld traceability records on all welding work.

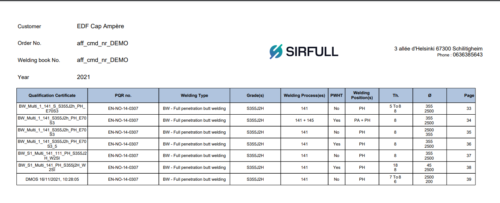

(image 1: Weldmapping tool – Sirfull Welding software)

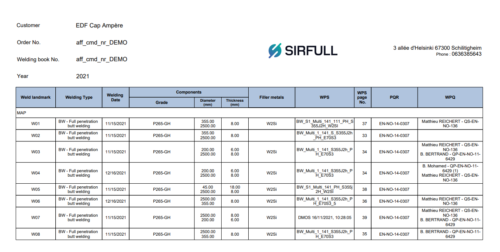

(image 2: Weld traceability record, Manufacturer Data Report PDF tool – Sirfull Welding software)

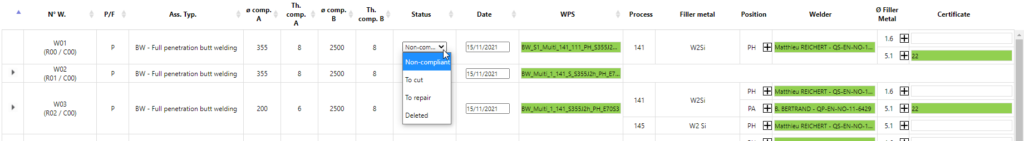

□ Non-Compliant Work

Work carried out by the contractor that does not meet the required specifications and/or standards, will be repaired and re-inspected by the contractor at the contractor’s cost. The Welding Coordinator’s decision on this matter shall be final.

(Image 3: Non-compliant management (repairing, cutting), Welding production monitoring tool – Sirfull Welding Software)

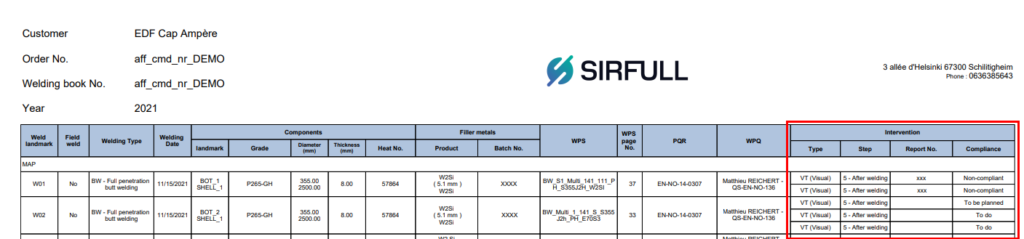

□ Inspection

Visual, NDE / NDT, destructive, or specialist inspectors shall meet the qualification and experience requirements as required by the applicable welding standard or specification, or as agreed by the Welding Coordinator.

NDE / NDT service providers shall make available all records and reports to the company and the contractor for review and approval.

(image 4: Non-compliant welds and NDE/NDR record number, MDR PDF – Sirfull Welding Software)

□ Welding Procedures

The Contractor shall be responsible for using a technically sound and proven Welding Procedure, that is supported by a WPQR meeting the applicable standard.

(image 5: Weld log, WPS and PQR baseline – Sirfull Welding software)

(image 6: WPS’s project list – MDR report – Sirfull Welding software)

□ Qualifications of Welding Personnel

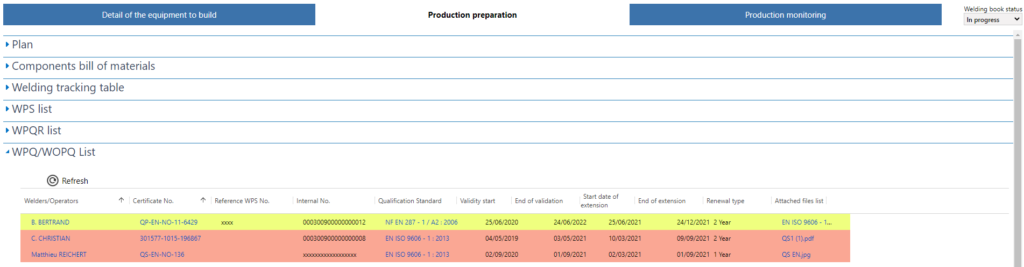

In all cases, the Contractor is to maintain a list of welding personnel and their qualifications. This list shall be submitted to the company on request.

(image 7: WPQ’s project list, the color scheme for renewals deadline – Sirfull Welding software)

□ Welding Consumables

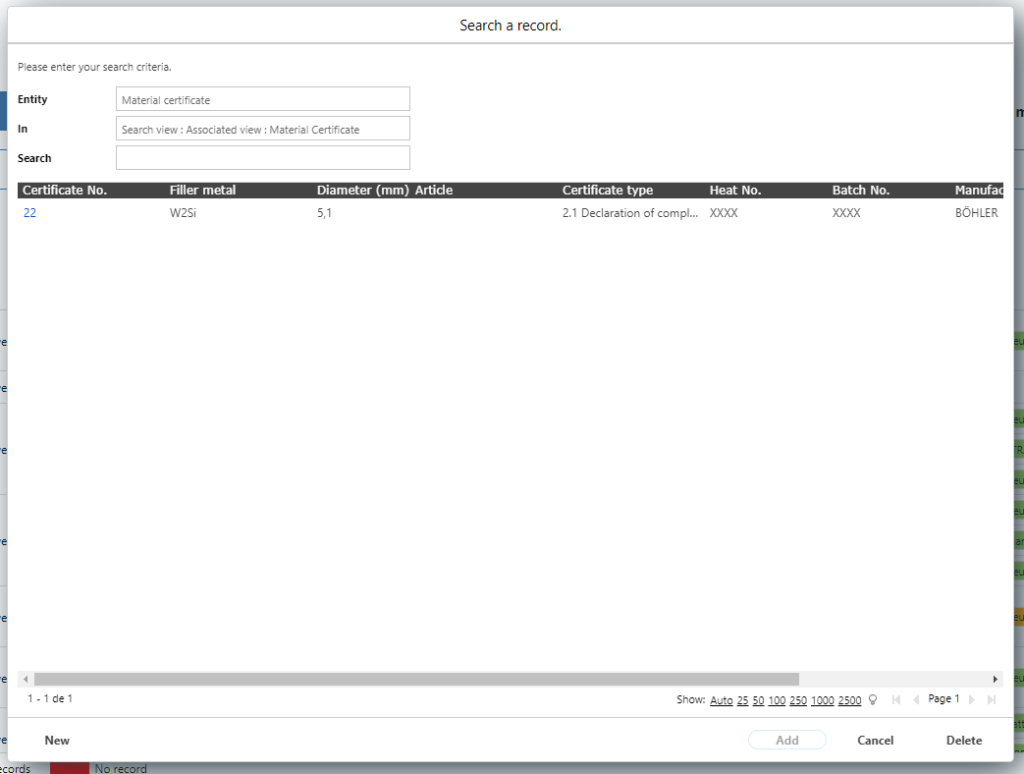

Welding consumables shall be positively identified in packaging or stampings, with batch certificates supplied.

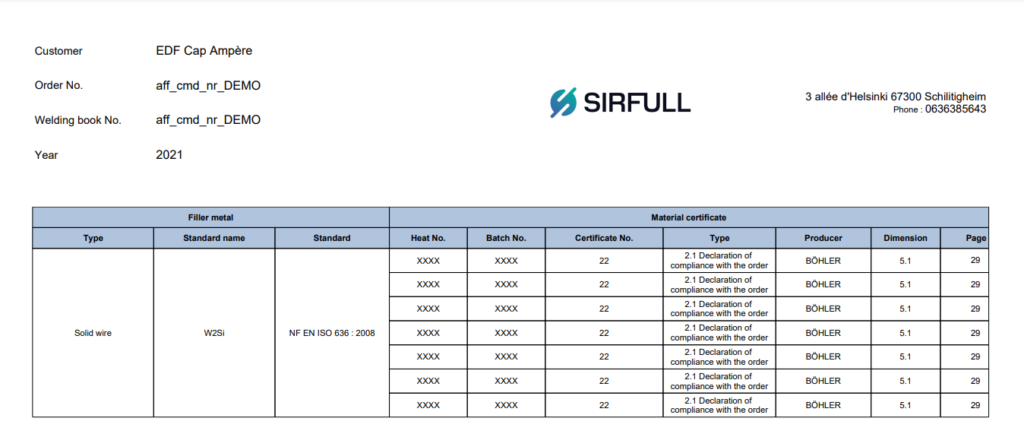

(image 8: Welding Consumables Certification Association – Sirfull Welding software)

(image 9: Welding Consumables Certification Association MDR PDF report – Sirfull Welding software)

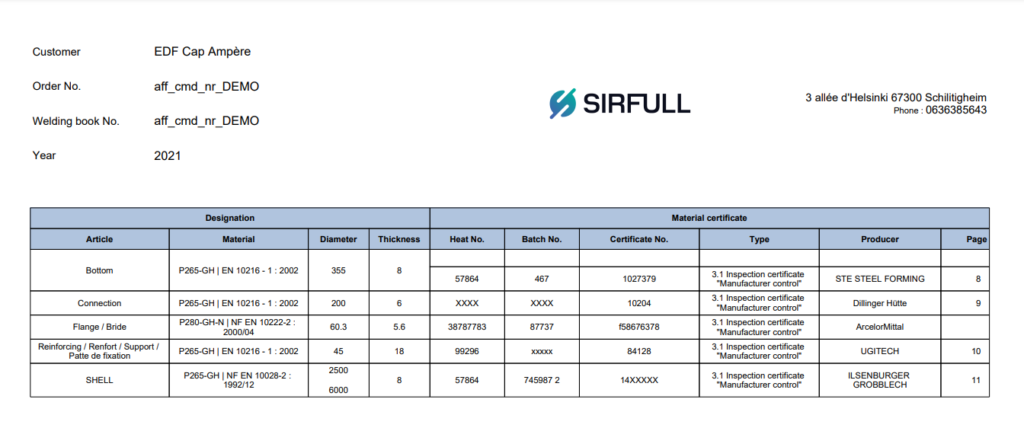

□ Material Certification or Bill of Material (BOM)

All Material Test certificates shall be incorporated into the MDR and forwarded to the welding coordinator for review and approval.

(image 9: Welding Material Certificate MDR PDF report – Sirfull Welding software)

Download our MDR sample for free.

Your next moves:

Contact us to learn more about Sirfull Welding and how to implement it in your company.

Try for free or book a Sirfull Welding demo here

Sirfull is a software vendor with a strong industrial culture and French know-how, which develops solutions that enable its customers to anticipate changes in their market.

More