Les secteurs industriels

couverts par SIRFULL

Chimie / Pharma

Pétrole et gaz

Nucléaire

Ouvrages & infrastructures

Ferroviaire

Equipements sous-pressions, chaudronnerie, mécanno-soudure, tuyauterie...

La culture SIRFULL

Prima di cominciare la vostra prova gratis…

…vi invitiamo a una dimostrazione online. Un esperto Sirfull Welding vi introdurrà al vostro ambiente di prova e vi darà le chiavi per sfruttare al meglio il mese di prova (videoconferenza, attendere 45 minuti).

PIANIFICA LA TUA DIMOSTRAZIONE

Gli accessi vi saranno consegnati dopo la dimostrazione.

Se non avete tempo per una dimostrazione, vi suggeriamo di guardare questo breve video di 7min : vedi il video dimostrativo

Before starting your trial…

…we invite you to an online demonstration. A Sirfull Welding expert will introduce you to your trial environment and give you the keys to take full advantage of your trial month (video conference, allow 45min).

Your credentials will be delivered to you after the demonstration.

If you don’t have time for a demonstration, we suggest you watch this quick overview of Sirfull Welding in 7min: see the video demonstration

Avant de débuter votre essai…

…nous vous invitons à une démonstration en ligne. Un expert Sirfull Welding vous présentera votre environnement d’essai et vous donnera les clés pour profiter pleinement de votre mois d’essai (vidéoconférence, prévoir 45min).

Les accès vous seront livrés après la démonstration.

Si n’avez pas le temps pour une démonstration, nous vous proposons de visionner ce rapide tour d’horizon de Sirfull Welding en 7min : voir la démonstration vidéo

[contact-form-7 id=”5690″ title=”Demande de test welding FR”]

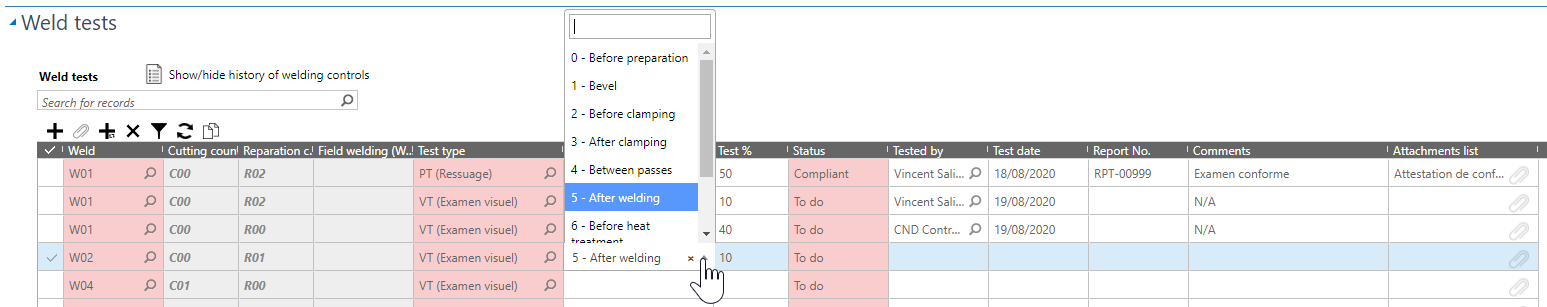

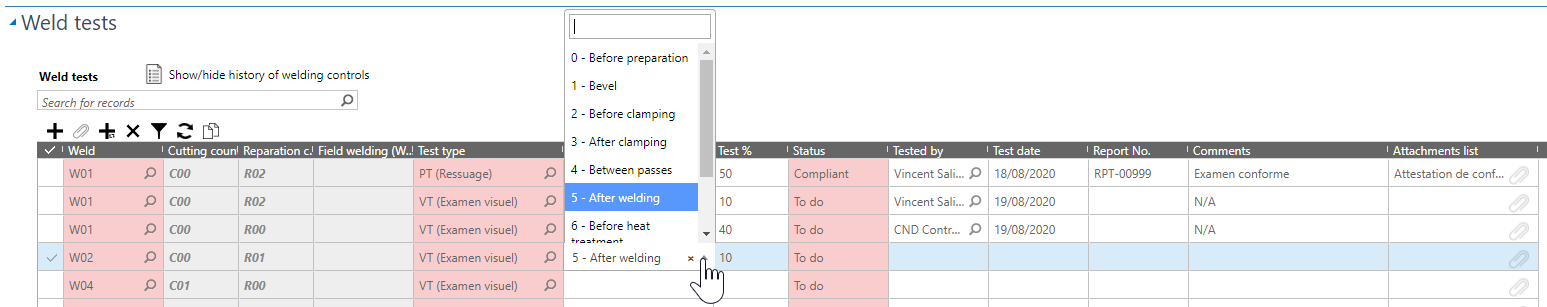

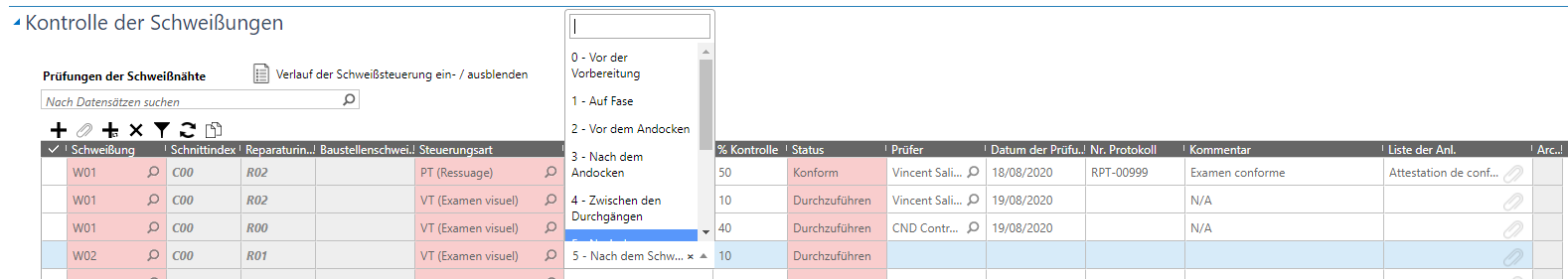

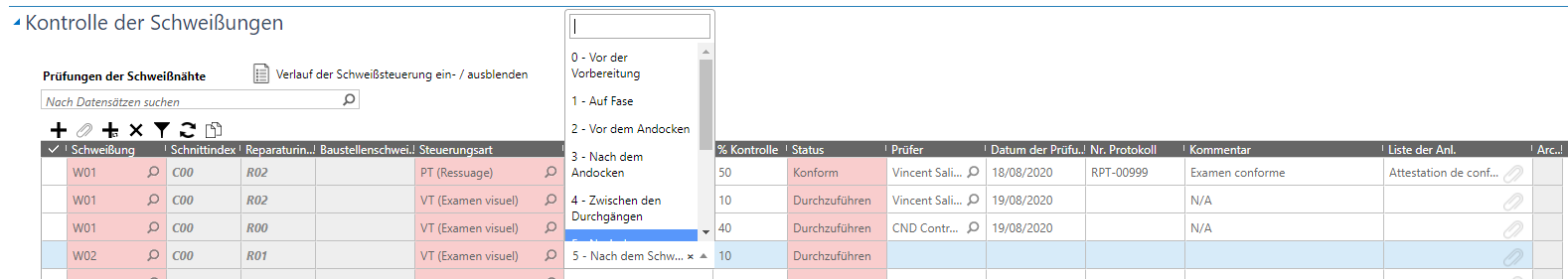

- Tenete d’occhio l’elenco generale dei CND della vostra produzione;

- Tracciate i rapporti di ogni CND ;

- Assegnare un controllore interno o esterno per ogni CND da effettuare.

- Gardez un œil sur la liste globale des CND de votre production;

- Attachez les Procès-Verbaux (PV) de chaque CND;

- Attribuez un contrôleur interne ou externe pour chaque CND à réaliser.

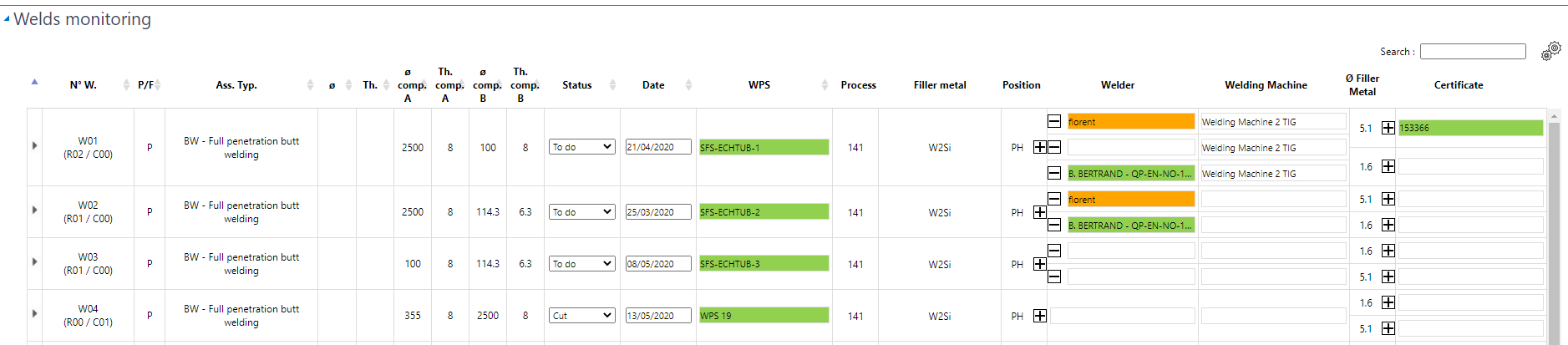

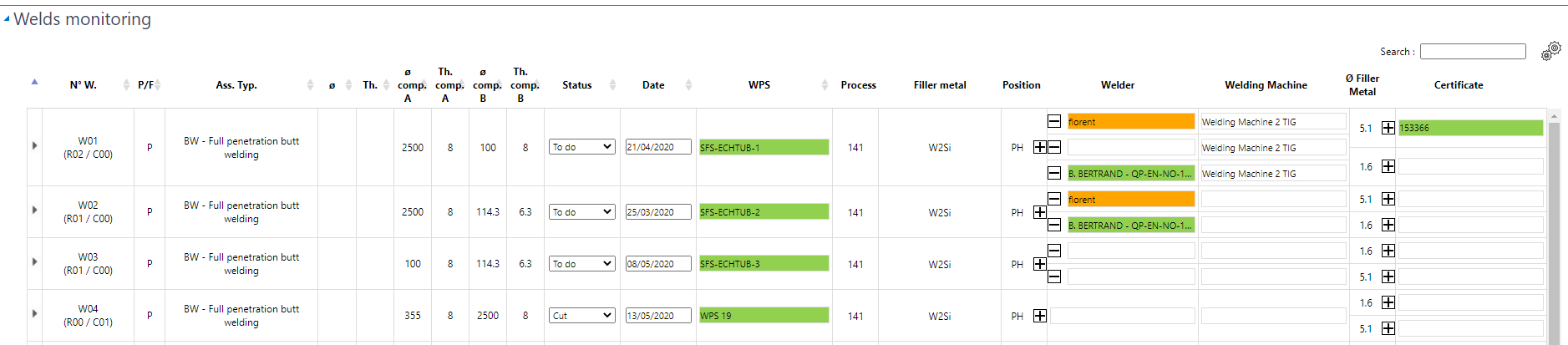

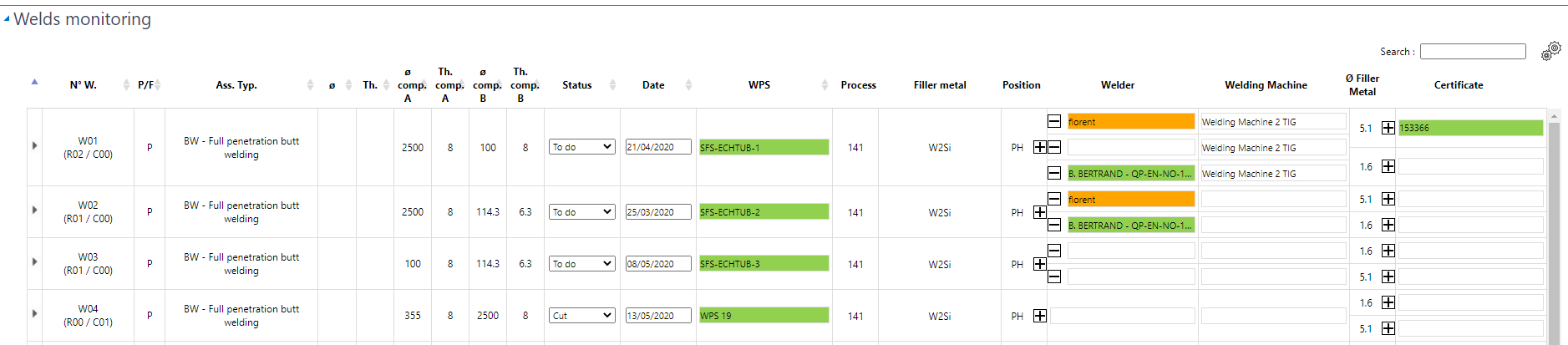

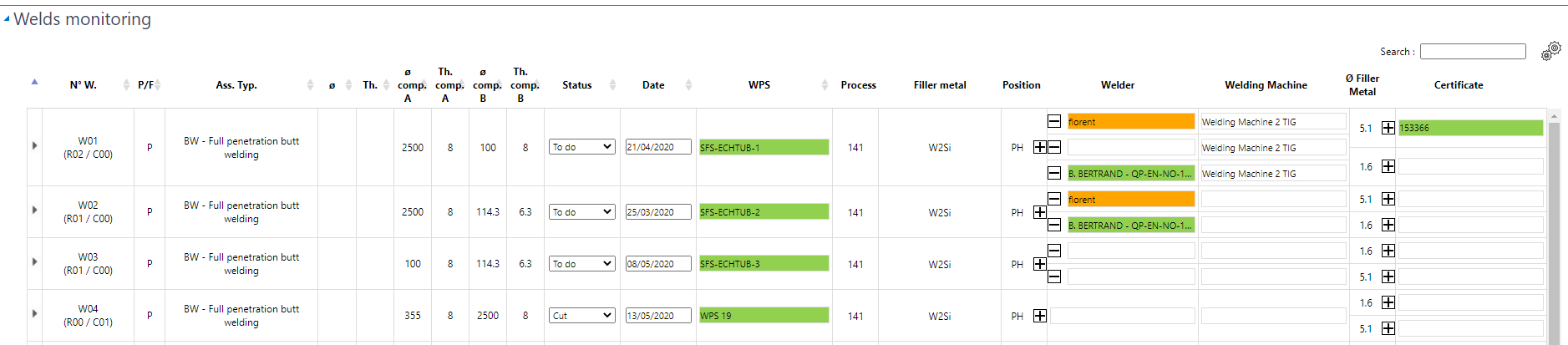

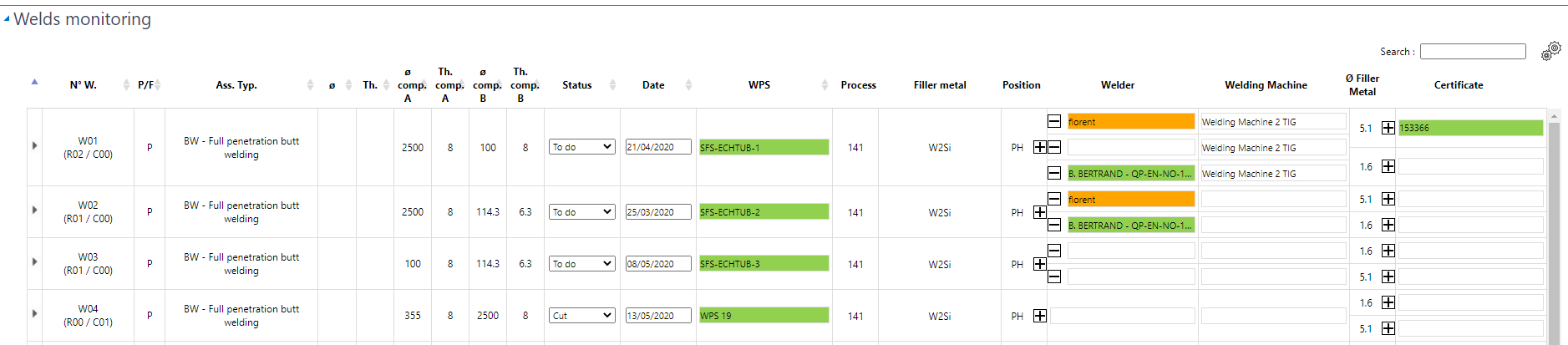

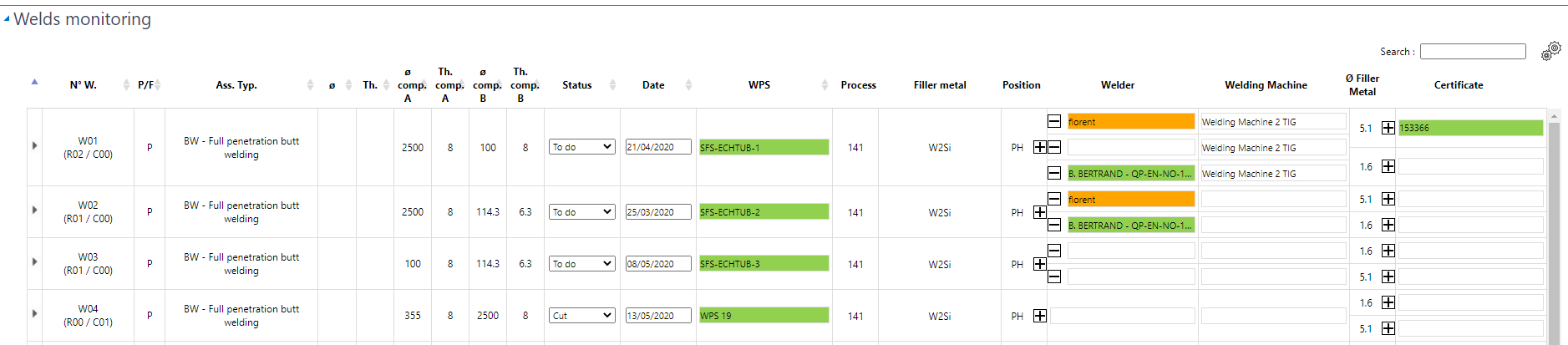

Welding project management

Find in one place all the information related to your welding projects and follow their progress.

WPS automatic drafting

Sirfull finds the optimal PQR covering the parameters of the weld to be performed in your case and writes a compliant WPS based on this PQR.

Weld mapping

Locate the welds and components of your equipment to be assembled on its plan and export it.

Welders and WPQR always qualified

Don’t miss any validation end date. Requalify every 6 months the WPQR, attach the supporting document and find in one click the requalification weld in the welder’s assembly history.

- Know how the welding was carried out, by whom, with which qualifications, material certificates, welding machines, …

- Easily assign the most qualified welder(s) to execute the job.

- Find the material and consumable certificates available for each weld.

- Keep an eye on the overall NDT list of your production;

- Trace the reports of each NDC;

- Assign an internal or external controller for each NDT to be carried out.

[contact-form-7 id=”6007″ title=”Demande de test welding EN_copy”]

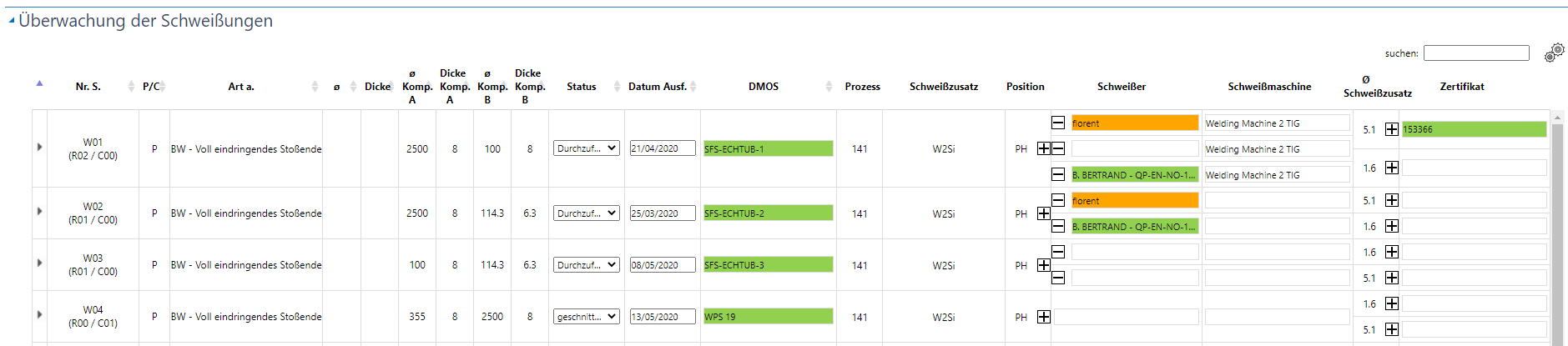

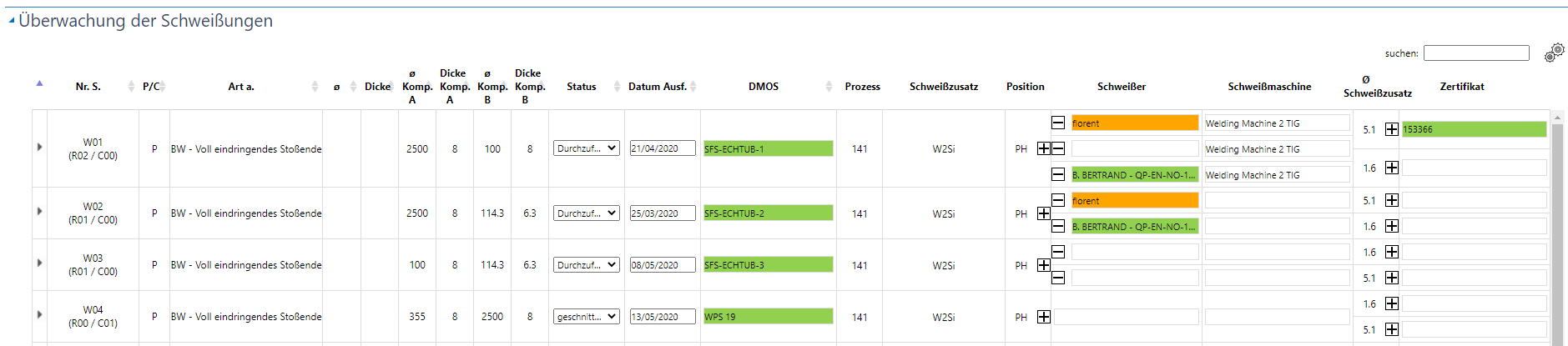

Betriebswirtschaft

Finden Sie an einer Stelle alle Informationen zu Ihrem Schweißbetrieb und verfolgen Sie deren Fortschritt.

Automatische WPS-Bearbeitung

Sirfull findet die optimale PQR, die die Parameter der in Ihrem Fall durchzuführenden Schweißung abdeckt, und schreibt aus dieser PQR eine konforme WPS.

Lage der Schweißnähte auf dem Plan

Legen Sie die Lage der zu montierenden Schweißnähte und Komponenten Ihrer Ausrüstung auf ihrem Plan aus und exportieren Sie ihn.

Schweißer und WPQ immer qualifiziert

Verpassen Sie kein Veröffentlichungsenddatum. Requalifizieren Sie alle 6 Monate die WPQ, fügen Sie das Begleitdokument bei und finden Sie mit einem Klick die Requalifizierungsschweißung in der Montagehistorie des Schweißers.

- – Verfolgen Sie, wie die Schweißnähte gemacht wurden, von wem, mit welchen Qualifikationen, Materialzeugnissen, Schweißmaschinen, …

- – Einfaches Zuweisen des/der qualifiziertesten Schweißers/Schweißer zur Durchführung der Schweißung.

- – Finden Sie die verfügbaren Materialzertifikate für jede Schweißnaht.

- – Behalten Sie die ZfP-Gesamtliste Ihrer Produktion im Auge;

- – Fügen Sie die Protokolle (PV) der einzelnen ZfPs bei;

- – Weisen Sie für jedes durchzuführende ZfP einen internen oder externen Controller zu.

- Sapere come è stata effettuata la saldatura, da chi, con quali qualifiche, certificati dei materiali, saldatrici, …

- Assegnare facilmente il saldatore o i saldatori più qualificati per eseguire il lavoro.

- Trovare il materiale e i certificati di consumo disponibili per ogni saldatura.

Gestione dei progetti di saldatura

Trovate in un unico posto tutte le informazioni relative ai vostri progetti di saldatura e seguitene l’andamento.

Stesura automatica WPS

Sirfull trova la PQR ottimale che copre i parametri della saldatura da eseguire nel vostro caso e scrive un WPS conforme basato su questa PQR.

Mappatura della saldatura

Individuare le saldature e i componenti della vostra attrezzatura da assemblare sul suo piano ed esportarla.

Saldatori e WPQR sempre qualificati

Non perdere nessuna data di fine convalida. Riqualificare ogni 6 mesi il WPQR, allegare il documento di supporto e trovare in un clic la saldatura di riqualificazione nella cronologia di assemblaggio del saldatore.

- Tracez comment les soudures ont été effectuées, par qui, avec quelles qualifications, certificats de matériaux, machines à souder, …

- Attribuez facilement le ou les soudeurs les plus qualifiés pour réaliser la soudure.

- Trouvez les certificats matières disponibles pour chaque soudure.

Gestion des affaires

Retrouvez en un point l’ensemble des informations relatives à vos affaires de soudage et suivez leur avancement.

Rédaction automatique des DMOS

Sirfull trouve la QMOS optimale couvrant les paramètres de la soudure à réaliser dans votre affaire et rédige un DMOS conforme à partir de cette QMOS.

Localisation des soudures sur plan

Disposez l’emplacement des soudures et des composants de votre équipement à assembler sur son plan et exportez-le.

Soudeurs et QS toujours qualifiés

Ne manquez aucune date de fin de validé. Requalifiez tous les 6 mois les QS, attachez la pièce justificative et retrouvez en un clic la soudure de requalification dans l’historique d’assemblage du soudeur.

WELDING SOFTWARE COMPARISON | |||||

FEATURES | SIRFULL | Weldnote | Weldeye | TWI | Weld assistant |

WELDING PREPARATION | |||||

PQR Management | ✓ | ✓ | ✓ | ✓ | ✓ |

Search through qualified PQR and Welder Qualifications approval ranges | ✓ | ✓ | × | ≈ | ≈ |

Automatic Approval Range Calculation | × | ✓ | × | ≈ | × |

Upload your existing PQR documents into the software | ✓ | ✓ | ✓ | × | ✓ |

Code Checking between WPS and PQR to ensure compliance (Warning you of any non-conformance) | ✓ | ✓ | ✓ | ✓ | × |

Automatic generation of WPS | ✓ | ✓ | ✓ | × | ✓ |

WPS translation into a secondary language | ✓ | ✓ | × | × | ✓ |

WPS template customization by user | ✓ | × | × | × | × |

PQR Management and Qualified welder identification in compliance with identified WPS | ✓ | ✓ | ✓ | ✓ | ✓ |

Notifications for welder qualifications that are about to expire | ✓ | ✓ | ✓ | × | ✓ |

Build in technical library of consummables that could be customized | ✓ | ✓ | ✓ | ≈ | ≈ |

Weld mapping on equipment plan (bubbling function) | ✓ | × | × | × | × |

WELDING MANUFACTURING | |||||

Welding project management | ✓ | ≈ | ✓ | ✓ | × |

Filler and materials certificates management | ✓ | ✓ | ✓ | × | × |

Full traceability of weld | ✓ | ✓ | ✓ | ✓ | × |

Weld status management (historization) | ✓ | ≈ | ≈ | ≈ | ≈ |

WPS and Welder performance management (percentage of repairs based on the number of welds completed) | ✓ | ✓ | × | ✓ | × |

Multiple company management | ✓ | ✓ | × | × | × |

User matrix rights | ✓ | ≈ | ≈ | ≈ | ≈ |

Weld sketch designer in the software | ≈ | ✓ | ✓ | ≈ | ≈ |

WELDING NDTs | |||||

NDTs scheduling | ✓ | × | ≈ | ✓ | × |

NDTs report management | ✓ | × | ✓ | × | × |

Automatic initialization of NDT schedules and specific monitoring dashboards | ≈ | × | × | ✓ | × |

NDT report creation | × | × | × | ✓ | × |

WELDING REPORTING | |||||

Welding data book pdf generator / customizable table of content / annexe document importation | ✓ | ≈ | ≈ | ≈ | × |

Manufacuring end report pdf generator / customizable table of content / annexe document importation | ✓ | × | × | ✓ | × |

Welding data book and Manufacuring end report translation into a secondary language | ✓ | ≈ | ≈ | ≈ | × |

Electronic signature | ✓ | × | × | × | × |

Customizable dashboard to follow up on the welding performance indicators such as quality rates, welder performance, non-compliance etc. | ✓ | × | × | × | × |

Weld cost calculation | × | × | × | ✓ | ✓ |

ADDITIONNAL FEATURES | |||||

ERP and/or IT systems integration interface | ✓ | × | ✓ | × | × |

Connection welding source | ✓ | ≈ | ✓ | × | × |

Excel import / export | ✓ | ≈ | ✓ | × | × |

Mass data importation (available with Swift Data additionnal module) | ✓ | × | × | × | × |

User friendly navigation | ✓ | ✓ | ✓ | × | ≈ |